Heat Sinks Explained: Design, Function, and Advancements in Thermal Management

Heat sinks are a fundamental part of modern electronic systems, designed specifically to control and disperse heat generated by internal components. As processors, graphics cards, and power circuits operate, they produce thermal energy that must be managed to prevent performance issues or hardware failure. Heat sinks serve as protective thermal solutions by transferring heat away from sensitive components and releasing it into the surrounding environment.

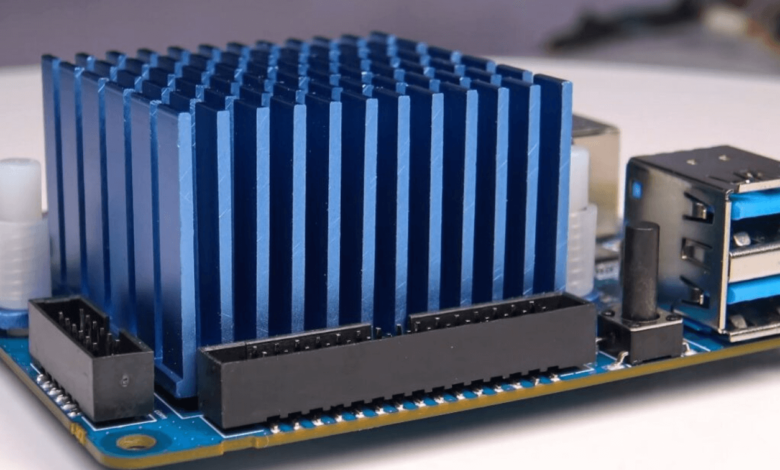

Available in a variety of configurations, passive, active, and hybrid, and commonly manufactured from aluminum or copper, heat sinks are essential to ensuring reliable operation and long-term durability.

This article provides a detailed overview of heat sinks, explaining what they are, how they work, the different types available, the materials used in their construction, and the role they play in modern and emerging technologies.

What Is a Heat Sink?

A heat sink is a cooling component used in electronic devices to regulate temperature by absorbing and dispersing heat produced during operation. It is typically mounted directly onto a heat-generating element such as a processor, integrated circuit, or power module.

Heat sinks function through two primary heat transfer processes: conduction and convection. Heat moves from the electronic component into the heat sink through conduction, facilitated by highly conductive materials like aluminum or copper. Once the heat enters the heat sink, convection allows it to move away from the surface and into the surrounding air. The fins or extended surfaces of the heat sink increase the exposed area, improving airflow interaction and heat dissipation.

What Does a Heat Sink Do?

The main function of a heat sink is to manage excess heat and keep electronic components operating within safe temperature limits. As components generate heat, the heat sink absorbs this thermal energy and redirects it away from sensitive areas, preventing overheating and potential damage.

Heat sinks improve thermal performance by expanding the surface area available for heat exchange. Their finned or structured designs allow heat to dissipate more efficiently into the environment. By maintaining stable operating temperatures, heat sinks help prevent thermal throttling, reduce system failures, and extend the lifespan of electronic devices.

Types of Heat Sinks

Heat sinks are generally classified into three categories based on their cooling method: active, passive, and hybrid.

Active Heat Sinks

Active heat sinks include mechanical components such as fans or liquid cooling systems to enhance heat removal. These systems force air or coolant across the heat sink, significantly improving heat transfer and cooling efficiency.

They are commonly used in high-power applications such as gaming computers, servers, and advanced industrial electronics where heat output is substantial. While effective, active heat sinks may introduce additional noise, consume more power, and require maintenance due to moving parts.

Passive Heat Sinks

Passive heat sinks operate without any powered components. They rely entirely on natural airflow and thermal conduction to dissipate heat. This makes them silent, energy-efficient, and highly reliable.

Passive heat sinks are often used in applications with lower heat output or where noise reduction is essential, including smartphones, LED lighting, IoT devices, and embedded systems. However, their cooling capacity can be limited in environments with restricted airflow or high thermal demands.

Hybrid Heat Sinks

Hybrid heat sinks combine features of both active and passive designs. They typically use fans or pumps alongside extended fin structures or advanced materials to balance cooling efficiency and noise levels.

These systems are well-suited for high-performance computing environments where effective thermal management is required without excessive acoustic output. The added complexity of hybrid designs can increase manufacturing costs and maintenance requirements, but they offer superior temperature control for demanding applications.

Heat Sink Materials and Technology

Heat sinks are most commonly made from aluminum and copper due to their thermal conductivity and durability.

Aluminum is lightweight, cost-effective, and easy to manufacture, making it a popular choice for many applications. Copper provides significantly higher thermal conductivity—approximately twice that of aluminum—allowing faster heat transfer, though it is heavier, more expensive, and more difficult to shape.

Advancements in heat sink technology include the development of composite materials, vapor chambers, and improved fin geometries. These innovations enhance heat distribution, increase surface area, and improve overall cooling efficiency, supporting the growing thermal demands of modern electronics.

What Is the Purpose of a Heat Sink?

Heat sinks are used across a broad range of electronic devices. In computers, they are essential for cooling CPUs and GPUs. In power supplies, heat sinks manage the heat produced during energy conversion. Compact devices such as smartphones and tablets also rely on heat sinks to regulate internal temperatures.

By controlling heat buildup, heat sinks protect electronic components from thermal damage, ensure consistent performance, and support reliable operation across various applications.

Read also: Transforming Industrial Automation with Advanced Motor Technology

Designing Efficient Heat Sinks

The performance of a heat sink depends heavily on its design, including its size, shape, surface area, and material composition. These factors influence how effectively the heat sink can absorb and dissipate heat.

Custom heat sink designs allow engineers to optimize cooling solutions for specific devices or operating environments. By tailoring the design to match thermal requirements, heat sinks can improve efficiency, reduce overheating risks, and enhance system longevity. With the rise of technologies such as 5G devices and high-density computing systems, thermal management challenges continue to grow. Heat sinks remain a critical component in maintaining temperature stability as electronic systems become smaller and more powerful.