The Hidden Risks of Using the Wrong Hose in Process Applications

Choosing the wrong hose for industrial processes creates problems that many engineers only discover after costly failures occur. What appears to be a simple purchase decision can trigger contamination issues, unexpected downtime, and serious safety incidents. These risks often remain invisible until operations face disruptions that could have been prevented through better initial selection.

The selection of a flexible hose for process applications demands careful attention to compatibility, pressure ratings, and environmental factors. Many procurement teams focus primarily on upfront costs, overlooking how material incompatibility or inadequate specifications compromise system integrity over time. A hose that works perfectly in one application might prove catastrophic in another, even when the visual differences seem minor to untrained eyes.

Product Contamination From Material Migration

Chemical Incompatibility Issues: Industrial processes handle diverse fluids, and hose materials must resist chemical attack from the substances they transport. Rubber compounds that work well with water-based solutions may degrade rapidly when exposed to petroleum products or aggressive solvents. This degradation releases particles into the process stream, contaminating products and compromising quality standards that customers expect.

Plasticiser Leaching Problems: Many rubber and polymer hoses contain plasticisers that improve flexibility but can migrate into process fluids under certain conditions. Food processing and pharmaceutical applications face particularly strict regulations about material contact, and plasticiser contamination violates these standards. Temperature fluctuations accelerate this leaching process, turning a seemingly suitable hose into a contamination source.

Leakage and System Pressure Failures

Pressure Rating Mismatches: Every hose carries specific working pressure and burst pressure ratings that define its safe operating envelope. Engineers sometimes select hoses based on average system pressures, forgetting about pressure spikes during pump starts, valve closures, or process upsets. A hose rated at 10 bar might seem adequate for an 8-bar system, yet transient spikes reaching 15 bar cause progressive damage that leads to eventual rupture.

Coupling and Ferrule Failures: The connection points between hoses and equipment represent critical weak spots in any fluid transfer system. Incorrect crimping specifications or mismatched coupling types create stress concentrations that initiate leaks. Even properly installed couplings fail when hose materials don’t match the ferrule design, allowing the hose to pull away under pressure or temperature changes.

Unsafe Flexing and Movement Concerns

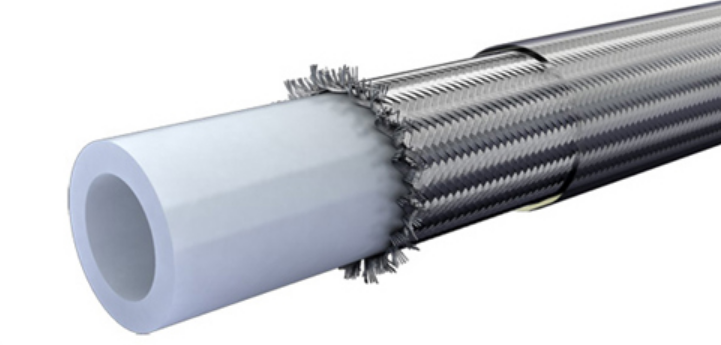

Minimum Bend Radius Violations: Every hose type has a minimum bend radius that prevents kinking and excessive stress on reinforcement layers. Tight installation spaces tempt installers to exceed these limits, creating sharp bends that restrict flow and damage the hose structure. Kinking reduces the effective diameter, increasing flow velocity and erosion rates whilst concentrating mechanical stresses that accelerate failure.

Dynamic Application Stresses: Hoses in applications with repeated flexing, vibration, or movement face fatigue stresses that static installations never experience. Assembly line robotics, mobile equipment, and reciprocating machinery subject hoses to millions of flex cycles over their service life. Standard hoses designed for static applications fail prematurely in these environments, sometimes catastrophically when pressurised fluids escape near workers.

See also: The Rise of Humanized AI: Transforming Technology with a Human Touch

Joint Fatigue and Connection Point Weakness

Cyclic Loading Effects: Pressure cycling creates repetitive stress patterns at hose-to-fitting interfaces where flexibility meets rigidity. Each pressure change causes microscopic material movement, and over thousands of cycles, this movement fatigues the hose material near the ferrule. Fatigue cracks typically initiate at these stress concentration points, propagating until sudden separation occurs during routine operation.

Vibration-Induced Loosening: Industrial equipment generates vibration that transmits through piping systems to hose connections. These vibrations can gradually loosen threaded connections or work-harden the hose material at attachment points. Regular inspection programmes sometimes miss these developing problems because the degradation occurs internally or at hidden connection points.

Regulatory Non-Compliance Consequences

Industry Standards Violations: Various industries mandate specific hose standards for safety and quality reasons. Food-grade applications require FDA-approved materials, whilst pharmaceutical processes demand USP Class VI compliance. Using non-compliant hoses might reduce immediate costs, but regulatory audits can shut down operations and trigger expensive retrofit projects. The consequences extend beyond fines to include product recalls and reputational damage.

Safety Certification Requirements: Certain applications require hoses that meet recognised safety standards such as those from fire protection systems or hazardous material handling. These certifications verify that hoses perform reliably under emergency conditions and resist specific hazards. Substituting uncertified alternatives creates liability exposures that insurance policies may not cover, leaving organisations vulnerable to catastrophic losses.

Long-Term Cost Implications

Understanding the true cost of hose selection requires looking beyond purchase prices to total ownership expenses:

- Emergency replacement costs including expedited shipping, overtime labour, and production losses typically exceed planned maintenance by 300-500 per cent.

- Contaminated product disposal, customer compensation, and quality investigation expenses can dwarf the savings from choosing cheaper hoses.

- Unplanned downtime ripples through production schedules, affecting delivery commitments and customer relationships in ways that financial calculations rarely capture.

- Workplace injuries from hose failures generate workers’ compensation claims, regulatory scrutiny, and potential legal liability that persists for years.

Conclusion

The technical selection of process hoses represents a critical engineering decision that affects safety, quality, and operational reliability across industrial facilities. Organisations that invest time in proper hose specification, considering material compatibility, pressure requirements, and application conditions, avoid the hidden costs of premature failures and regulatory problems. Take the time to evaluate your current hose selections against actual operating conditions, and consult with technical specialists who can guide you towards solutions that protect your processes, your people, and your profitability.