Transforming Construction and Manufacturing with Hot Melt Adhesives and Films

The Hot Melt Adhesive & Films industry has become a cornerstone of modern construction and manufacturing, delivering solutions that are efficient, reliable, and adaptable. While these materials often go unnoticed in finished products, their impact is significant—from packaging and automotive interiors to waterproofing systems in buildings. Among the innovations shaping the industry today is the use of PU waterproof membrane bonded with hot melt adhesives, which offers enhanced protection, durability, and installation efficiency in construction projects.

Understanding Hot Melt Adhesives and Films

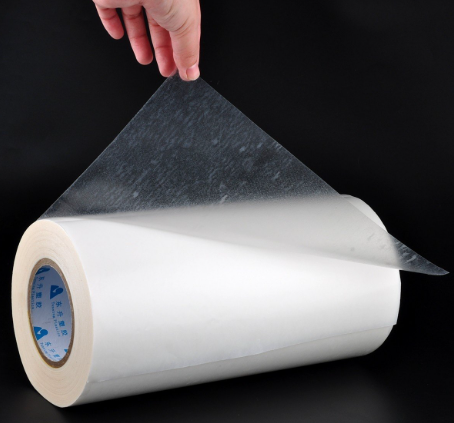

Hot melt adhesives are thermoplastic compounds that are applied in a molten state and solidify upon cooling, forming a strong bond between materials. Hot melt films operate on a similar principle, but they are supplied in solid sheets or rolls and activate through heat and pressure. Both forms are valued for their fast bonding, clean application, and ease of integration into automated production lines.

Unlike traditional solvent-based adhesives, hot melt adhesives do not require lengthy drying or curing periods. This not only reduces energy consumption but also allows manufacturers and construction professionals to maintain high-speed production while ensuring consistent bonding quality.

Applications Driving Industry Growth

Packaging and Consumer Products

One of the largest markets for hot melt adhesives and films is packaging. Products such as cartons, trays, labels, and flexible packaging require strong bonds that can withstand handling, stacking, and transportation. Hot melt adhesives perform reliably on various substrates, including corrugated board, coated paper, and plastics.

The growth of e-commerce and global logistics has increased demand for packaging solutions that are both efficient and durable. Hot melt adhesives allow high-speed production lines to operate without delays while maintaining the structural integrity of packaged goods.

Construction and Waterproofing Solutions

Construction applications are another major driver of hot melt technology, especially in waterproofing. Water infiltration can lead to structural damage, mold growth, and long-term maintenance issues. PU waterproof membrane has emerged as a preferred material for creating effective barriers against moisture in areas such as roofs, basements, balconies, and bathrooms.

When PU waterproof membrane is bonded using hot melt adhesives, it creates a seamless, durable barrier that protects structures from water damage. The rapid curing and strong adhesion of hot melt adhesives reduce installation time, lower labor costs, and ensure a reliable waterproofing solution. Additionally, hot melt systems allow for precise application, minimizing material waste and enhancing overall project efficiency.

Automotive and Industrial Applications

The automotive sector extensively uses hot melt adhesives and films for interior components, including headliners, carpets, door panels, and insulation layers. These adhesives must withstand vibration, temperature fluctuations, and prolonged stress without losing bond strength.

Hot melt films provide uniform adhesion, which ensures both functional performance and visual quality. Lightweight bonding solutions also contribute to fuel efficiency by reducing the overall weight of vehicles. The versatility of hot melt adhesives allows them to bond various substrates, including plastics, metals, and composites, making them essential in automotive and industrial manufacturing.

See also: How Christmas DTF Transfers Support Print-on-Demand Businesses During Peak Season

Performance Characteristics of Hot Melt Solutions

Speed and Production Efficiency

Rapid bonding is a key advantage of hot melt adhesives. Unlike liquid adhesives that require curing or drying, hot melts solidify quickly, allowing immediate handling and downstream processing. This property is particularly beneficial in high-volume production environments, reducing delays and increasing throughput.

Fast-setting adhesives also integrate seamlessly with automated equipment, ensuring consistent quality and efficient production, whether in manufacturing lines or construction sites.

Strength, Durability, and Flexibility

Hot melt adhesives and films are engineered to maintain strong, durable bonds over time. They resist heat, moisture, and aging, ensuring that bonded components remain secure throughout their lifecycle. In construction, bonding PU waterproof membrane requires adhesives that can endure environmental stressors while maintaining structural integrity.

Flexibility is another critical property. Applications such as roofing, flooring, and balconies require materials that can accommodate movement or expansion without compromising adhesion. Advances in polymer science allow hot melt adhesives to be customized for specific strength, elasticity, and temperature tolerance requirements.

Sustainability and Environmental Considerations

Cleaner Production Processes

Sustainability is a priority in modern manufacturing and construction. Hot melt adhesives are typically solvent-free, reducing volatile organic compound (VOC) emissions and promoting cleaner, safer working environments. This supports regulatory compliance and demonstrates a commitment to environmentally responsible practices.

Cleaner processes are particularly important in construction, where large-scale adhesive application could otherwise contribute to environmental pollution.

Material Efficiency and Waste Reduction

Hot melt films enable precise adhesive application, reducing material waste and eliminating unnecessary usage. In many cases, hot melt bonding replaces mechanical fasteners or multi-step assembly processes, streamlining production and installation while conserving resources.

This precision not only lowers costs but also aligns with sustainable manufacturing and construction practices by minimizing the environmental footprint of projects.

Recycling and End-of-Life Compatibility

As recycling and circular economy initiatives grow in importance, the compatibility of adhesives with material recovery processes becomes critical. PU waterproof membrane bonded with hot melt adhesives is often designed to separate cleanly or remain neutral during recycling, ensuring that materials can be reused or safely disposed of without contamination. This contributes to sustainable construction practices and long-term environmental responsibility.

Innovation and Customization in Hot Melt Technologies

Tailored Formulations

Customization is a defining trend in the hot melt adhesives and films industry. Manufacturers can adjust viscosity, open time, elasticity, and temperature resistance to match application-specific requirements. Tailored adhesives optimize performance for bonding PU waterproof membrane, automotive interiors, packaging, or technical textiles.

Collaboration between suppliers and end users ensures that adhesive solutions meet precise performance criteria, reduce downtime, and improve product quality.

Advances in Application Equipment

Innovations in application equipment complement material advancements. Modern dispensing and lamination systems provide precise temperature control, accurate placement, and high-speed operation. Automation and smart monitoring systems enhance reliability, reduce errors, and maintain consistent quality across production lines or construction projects.

Challenges and Opportunities

Despite strong growth, the industry faces challenges such as fluctuating raw material costs, regulatory changes, and increasing demands for performance and sustainability. However, these challenges present opportunities for innovation.

Companies that invest in research, develop sustainable materials, and provide customized solutions are better positioned to meet market demands. The rising need for PU waterproof membrane in construction, combined with the broad use of hot melt adhesives in automotive and packaging industries, highlights the continued growth potential of this sector.

Conclusion

The Hot Melt Adhesive & Films industry has become a vital part of modern construction and manufacturing, offering solutions that combine speed, reliability, and environmental responsibility. From automotive interiors and packaging to construction applications involving PU waterproof membrane, hot melt adhesives and films ensure consistent, durable, and efficient performance. As innovation in materials and application technology continues, this industry is well equipped to support the evolving needs of manufacturers and construction professionals while promoting sustainable and high-quality production practices.