Oil purifier machine overview

Introduction

Oil is a crucial component in many industrial and mechanical systems, providing lubrication, insulation, and cooling. Over time, oils get contaminated by dirt, moisture, gases, and other impurities, which can degrade their performance and harm equipment. An oil purifier machine is designed to remove these contaminants, restoring oil quality and extending its usable life. This article explores the purpose, working principle, types, benefits, and maintenance of oil purifier machines.

Why oil purification is necessary

Industrial oils, whether used in transformers, engines, hydraulic systems, or turbines, can accumulate impurities during operation. Contaminants like water, sludge, particulate matter, and dissolved gases lower the oil’s effectiveness. This results oil purifier machine in increased wear and tear on machinery, reduced efficiency, and higher operating costs. Purifying oil helps maintain optimal performance, protects equipment, and reduces environmental waste.

Working principle of oil purifier machine

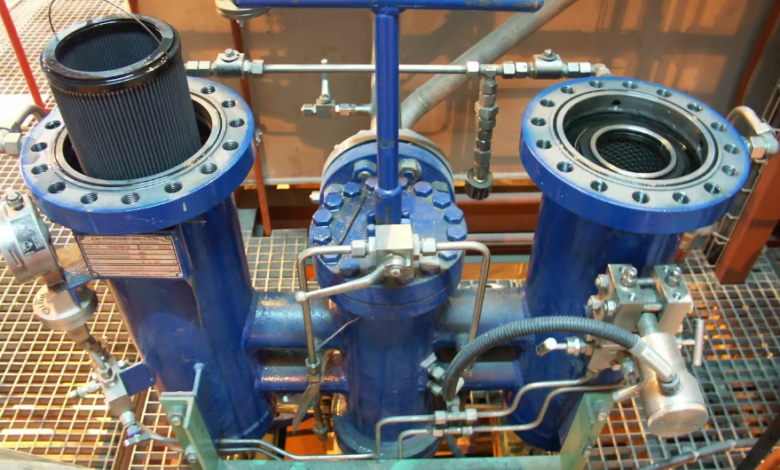

Oil purifier machines operate through a combination of processes designed to separate contaminants from the oil. Key processes include:

filtration

Solid particles and sludge are removed by passing the oil through fine filters. This protects equipment from abrasion and clogging.

vacuum dehydration

Water present in the oil is removed by creating a vacuum environment that lowers the boiling point of water, causing it to evaporate at lower temperatures. The vapor is then evacuated, drying the oil.

degassing

Dissolved gases are separated from the oil to improve its insulating and lubricating properties. This is typically achieved through vacuum or centrifugal methods.

The combination of these processes ensures the oil is cleaned thoroughly without damaging its essential properties.

Types of oil purifier machines

Oil purifier machines come in various designs tailored to different applications and scales:

portable oil purifiers

Compact and mobile units suitable for fieldwork or small-scale applications, allowing easy transportation and quick oil treatment.

stationary oil purifiers

Large, fixed installations used in factories, power plants, or workshops where continuous or high-volume purification is required.

online oil purifiers

Integrated with machinery to continuously purify oil during operation, preventing contamination buildup and ensuring consistent performance.

Benefits of using oil purifier machines

cost savings

Purifying oil extends its life, reducing the need for frequent replacements and saving money on oil purchases and disposal.

equipment protection

Removing contaminants minimizes wear and tear, preventing costly breakdowns and extending machinery lifespan.

environmental impact

Recycling and purifying oil reduce waste generation and environmental pollution from oil disposal.

improved efficiency

Clean oil improves lubrication and insulation, enhancing the overall efficiency of mechanical and electrical systems.

safety

Removing water and gases reduces risks related to corrosion, short circuits, or mechanical failures.

See also: How Do Tech Companies Source Critical CPU Components?

Industries that benefit from oil purifier machines

- power generation: Transformer oil purifiers maintain insulation oil quality in power transformers.

- manufacturing: Hydraulic and lubricating oils in machinery benefit from purification.

- marine and automotive: Engine oils and lubricants are cleaned to improve performance.

- petrochemical: Purifiers help maintain process oils and coolants.

- mining and heavy equipment: Oils used in heavy machinery are purified to reduce downtime.

Maintenance of oil purifier machines

Proper maintenance is essential to ensure the effectiveness and longevity of oil purifier machines:

- Regularly replace or clean filters to maintain flow and filtration quality.

- Inspect vacuum pumps and compressors for proper operation.

- Monitor oil quality before and after purification to ensure machine efficiency.

- Check seals and connections for leaks.

- Train operators on safe and correct usage.

challenges and solutions in oil purification

handling heavily contaminated oil

Initial contamination levels may require pre-treatment or staged purification to avoid overloading the system.

machine downtime

Scheduling regular maintenance minimizes unexpected breakdowns and ensures continuous operation.

cost considerations

Investing in advanced purification technology can reduce long-term expenses by minimizing oil consumption and equipment failures.

conclusion

An oil purifier machine is a vital asset for industries relying on oil for lubrication, cooling, and insulation. By removing moisture, gases, and solid contaminants, these machines extend oil life, enhance equipment performance, and promote environmental sustainability. Selecting the right type of oil purifier and adhering to maintenance protocols ensures operational efficiency and cost savings, making oil purification an essential practice across many sectors.