Siemens Servo Motor CAD: Design and Industrial Applications

Introduction to Siemens Servo Motor CAD

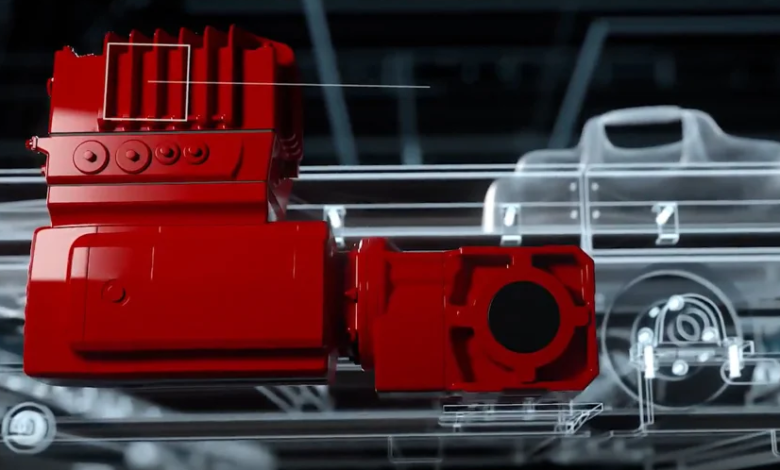

Siemens servo motor CAD plays a pivotal role in modern engineering and industrial automation. By leveraging computer-aided design (CAD), engineers can create, simulate, and optimize siemens servo motor designs before manufacturing. This approach enhances precision, reduces errors, and shortens development time. In industries like robotics, automation, CNC machinery, packaging, and medical equipment, siemens servo motor CAD allows engineers to achieve optimal performance and integration.

The Role of CAD in Siemens Servo Motor Design

Computer-aided design (CAD) is essential in developing high-performance siemens servo motors. CAD software enables engineers to model motor components such as the rotor, stator, housing, and feedback systems in a virtual environment. This allows for precise dimensioning, assembly simulation, and stress analysis.

Using siemens servo motor CAD, engineers can predict mechanical and thermal performance, ensuring the motor meets required specifications. Simulations help identify potential issues such as excessive heat, vibration, or misalignment, which can be addressed before production.

Key Features of Siemens Servo Motor CAD

Siemens servo motor CAD offers numerous advantages over traditional design methods:

- Precision Design: High-accuracy modeling ensures components fit together seamlessly and operate efficiently.

- Simulation Capabilities: Engineers can test torque, speed, vibration, and thermal performance virtually.

- Time and Cost Efficiency: Early detection of design flaws reduces prototype costs and shortens development cycles.

- Documentation: CAD provides detailed drawings and specifications necessary for manufacturing and assembly.

- Flexibility: Design modifications can be implemented quickly and analyzed immediately, allowing rapid iteration.

See also: Smart City Living: How Technology is Revolutionizing Property Investment

Industrial Applications of Siemens Servo Motor CAD

Siemens servo motor CAD is applied across various industries due to its versatility and precision:

Robotics and Automation

In robotics and automated production lines, CAD allows engineers to design motors that fit precisely within robotic arms and conveyors. Accurate modeling ensures smooth motion control, high repeatability, and minimal mechanical interference.

CNC Machinery

CNC machines require highly precise motor components. Siemens servo motor CAD helps in designing motors optimized for speed, torque, and thermal performance. This improves machining accuracy, reduces material waste, and enhances overall system efficiency.

Packaging Industry

Packaging machines rely on precision motors for labeling, filling, and sorting. CAD modeling ensures that siemens servo motors can be integrated seamlessly into complex packaging systems, providing accurate speed and position control.

Medical Equipment

Medical devices require compact, precise, and reliable motors. Using siemens servo motor CAD, engineers can design motors that meet strict dimensional and performance requirements, ensuring safe operation and high reliability in devices like diagnostic machines and surgical equipment.

Renewable Energy and Transportation

Siemens servo motor CAD is also used in renewable energy systems, such as solar trackers and wind turbines, for efficient energy conversion. In transportation, CAD helps design electric drive systems that optimize energy use and provide reliable performance.

Advantages of Using Siemens Servo Motor CAD

Implementing siemens servo motor CAD in motor design offers several benefits:

- Enhanced Accuracy: Virtual modeling ensures all components meet precise tolerances.

- Reduced Development Costs: Early problem detection reduces the need for multiple physical prototypes.

- Improved Efficiency: CAD allows engineers to optimize motor design for torque, speed, and energy consumption.

- Faster Development: Design iterations and simulations accelerate the time from concept to production.

- Documentation and Compliance: CAD provides complete technical documentation for manufacturing, testing, and certification processes.

Best Practices for Siemens Servo Motor CAD

To maximize the benefits of siemens servo motor CAD, engineers should follow these practices:

- Detailed Component Modeling: Include all mechanical and electrical components for accurate simulation.

- Thermal and Stress Analysis: Simulate heat dissipation and mechanical stress to ensure durability.

- Integration Simulation: Test motor placement and interaction with other system components.

- Iterative Design: Use CAD simulations to refine the motor design before prototyping.

- Collaboration: Share CAD models with production, quality, and maintenance teams for seamless manufacturing and installation.

Future Trends in Siemens Servo Motor CAD

Siemens servo motor CAD technology continues to evolve, with trends that enhance industrial design and automation:

- Integration with IoT and Digital Twins: CAD models can be linked to digital twins for real-time performance monitoring.

- AI-Assisted Design: Artificial intelligence can optimize motor designs by analyzing multiple performance parameters simultaneously.

- Cloud-Based Collaboration: Engineers can work on CAD models remotely, improving global collaboration and accelerating design cycles.

- Sustainable Design: CAD enables the creation of energy-efficient motors that reduce power consumption and environmental impact.

These trends are expected to expand the capabilities of siemens servo motor CAD, enabling more efficient, precise, and innovative industrial designs.

Conclusion

Siemens servo motor CAD is a cornerstone of modern motor design, enabling precise, efficient, and reliable engineering solutions. By leveraging CAD tools, engineers can create motors optimized for performance, energy efficiency, and integration into complex industrial systems.

From robotics and CNC machinery to medical equipment, packaging, renewable energy, and transportation, siemens servo motor CAD ensures that motors meet the highest standards of precision and reliability. By adopting best practices and embracing emerging trends, professionals can reduce development time, lower costs, and produce high-quality motors that meet industrial demands.

Siemens servo motor CAD is not just a design tool; it is a pathway to innovation, efficiency, and future-ready industrial solutions.