Automation Trends in Modern Bottle Filling Machines

Automation has taken a dominant position in modern manufacturing, revolutionizing production processes across all industries, including the bottle filling machine business.

While efficiency, consistency, and increased daily output are the global pursuit, bottle filling machines are now an integral part of every food and beverage, cosmetics, and household goods company.

This shift toward automation stems from the need to maximize production efficiency, reduce human error, and ensure product quality. This article will explore current automation trends in bottle filling machines, their advantages, technologies, and their impact on the industry.

The Rise of Automation in Bottle Filling Machines

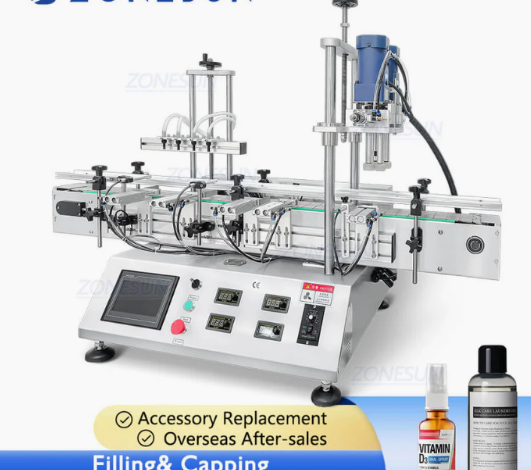

Bottle filling machines have made tremendous progress, evolving from manual operations to today’s automated processes. Automation significantly reduces human intervention in repetitive processes, delivering significant advantages in speed, accuracy, and consistency.

Traditionally, operators in filling operations manually controlled product movement, adjusted liquid levels, and controlled production flow. Today, filling machines can automatically sort, fill, cap, and label bottles, with precision ensuring that each bottle receives the exact amount required.

See also: Why Prevention Matters for Home Plumbing

Key Technologies Driving Automation

The power of modern bottle filling machines lies in the cutting-edge automation-driven technologies. Below are several technologies that benefit the industry:

1. Servo Motors and Drive Systems

Servo motors are increasingly becoming standard equipment in new filling machines. They provide full control of the filling process and can easily vary the flow rate and number of bottles filled.

Compared to traditional motors, servo motors offer greater speed, flexibility, and energy efficiency. They can be easily programmed to fill different bottle types and sizes, making them a viable solution for manufacturers with multiple product lines.

2. Robotic Integration

The application of robotics in filling machines is another leading automation trend. The increasing use of robotic arms in processes such as bottle placement, capping, and packaging not only reduces labor costs but also increases the speed and accuracy of these processes.

Robots can operate continuously for extended periods, even under heavy loads, maximizing production line efficiency. They can also perform tasks that would otherwise require manual shutdown and restart, reducing downtime.

3. Vision Systems for Quality Control

Vision systems are a crucial component of automated bottle filling machines. Vision systems use cameras and advanced image processing software to inspect filled bottles for defects, ensuring that products are in optimal condition before reaching the end customer.

Vision systems can identify defects such as underfilled bottles, loose caps, or misplaced labels, ensuring that only high-quality products are packaged and shipped to market.

4. IoT Connectivity

IoT-connected bottle filling machines inject additional intelligence into automated processes. Connected machines enable manufacturers to remotely monitor and control equipment and receive real-time information on key performance indicators such as output, speed, and product quality.

IoT connectivity enables predictive maintenance, alerting operators if and when maintenance is required, thereby avoiding unplanned downtime and reducing repair costs. Furthermore, data from IoT systems can even be analyzed to optimize production and identify inefficiencies.

Benefits of Bottle Filling Machine Automation

Automating bottle filling machines offers numerous benefits, all of which relate to increased operational efficiency and cost savings.

The greatest advantage of automated bottle filling machines is their ability to process larger volumes at higher rates. Machines no longer need to be shut down for routine interruptions or repositioning, significantly increasing production levels. Mechanized systems can fill thousands of bottles per hour, making them ideal for businesses that consistently produce high volumes.

Automated filling enables manufacturers to fill each bottle with the exact same amount of product, which is particularly important in food and beverage manufacturing, where product consistency and compliance are paramount. Automated equipment also reduces the potential for human error, which can lead to product scrap or rejected batches.

While the initial investment in an automated filling machine is high, the long-term benefits are significant. Automation can lower labor costs, reduce labor expenses, and eliminate product waste caused by human error. Furthermore, automated machines are cheaper to maintain than traditional equipment, reducing repair costs.

Automated machines can perform hazardous tasks that would otherwise be dangerous for workers. Working in a factory, such as handling chemicals or hot water, can be hazardous enough. Automation can make these tasks safer, enabling machines to perform them safely and reducing worker exposure to workplace hazards.

Conclusion

Automation in modern bottle filling machines has become a driving force for production line efficiency and consistency across a wide range of industries. A key trend lies in the integration of multiple technologies.

These technologies not only increase production speeds but also ensure high quality standards, reduce human error, and minimize downtime.

Automation enables manufacturers to save costs, increase productivity, and maintain a competitive advantage. Automation is helping the bottle and can industry create more efficient and reliable manufacturing processes.